How accurate is your sulfur dioxide testing?

Greg Howell – Vintessential Laboratories

Introduction

Last year we reported in this journal about the work we were doing to develop test kits for sulfur dioxide (SO2) and some surprisingly high results we got for “low preservative” wines we purchased from supermarket shelves. Since then we have completed the project and now have commercially available test kits for both Free Sulfur Dioxide (F SO2) and Total Sulfur Dioxide (T SO2) for spectrophotometers and automated analysers (the latter commonly known as Discrete Analysers).

Last year we reported in this journal about the work we were doing to develop test kits for sulfur dioxide (SO2) and some surprisingly high results we got for “low preservative” wines we purchased from supermarket shelves. Since then we have completed the project and now have commercially available test kits for both Free Sulfur Dioxide (F SO2) and Total Sulfur Dioxide (T SO2) for spectrophotometers and automated analysers (the latter commonly known as Discrete Analysers).

The test kits we developed have been well accepted in the marketplace, however the introduction was not without concerns from a few winemakers and lab analysts. These concerns related to the accuracy of the kits, however in all cases we were able to demonstrate that the kits were very accurate and, in fact, it was the existing testing in the winery that was not as accurate as the winemaker/lab analyst originally thought!

Sulfur dioxide testing in wineries

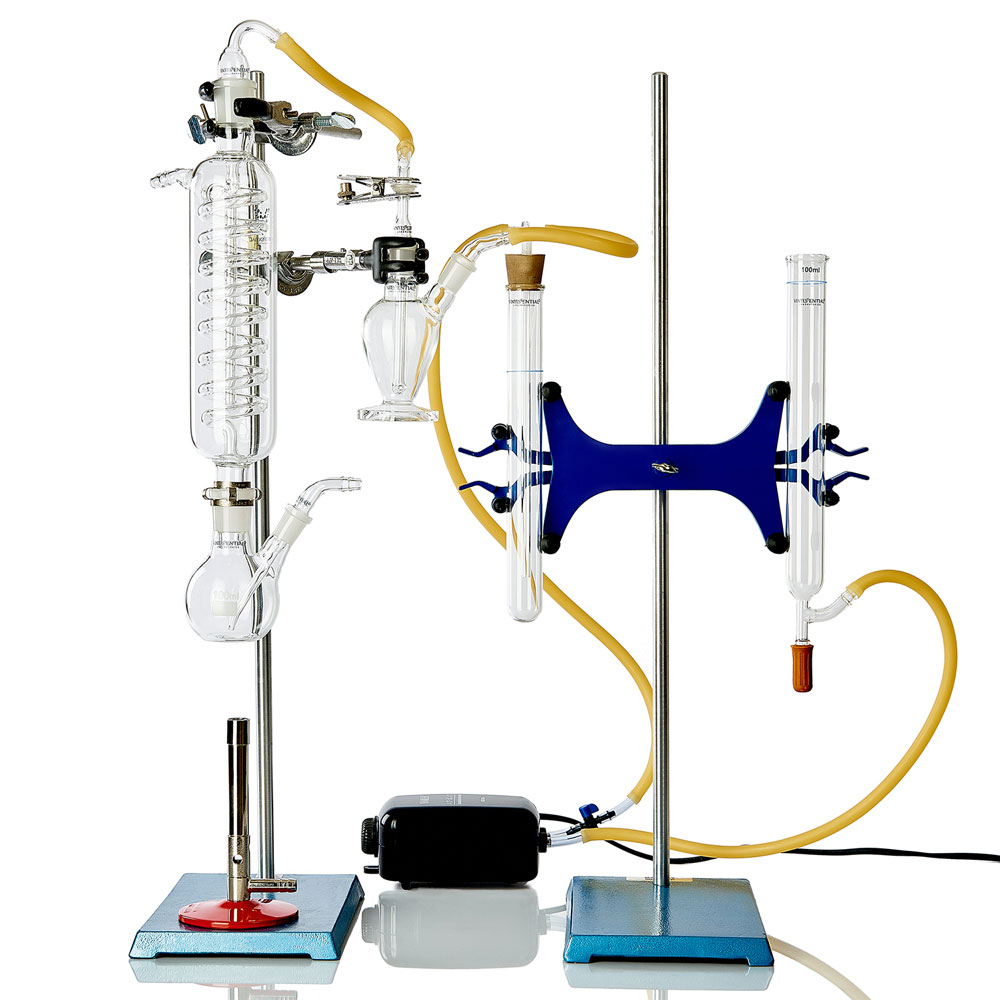

From our observations, the most common technique used throughout Australia and New Zealand for measuring SO2 in wine is the Aspiration/Oxidation (AO) technique, commonly known as the Rankine method. This very old technique uses classical glassware (see Figure 1) to aspirate the acidified sample, and then captures and oxidises the released SO2 in a flask, the contents of which are then titrated using sodium hydroxide. Done correctly, it works very well, although it is laborious and uses some dangerous chemicals.

There are several aspects of this technique that must be calibrated and checked in an ISO17025 accredited laboratory like ours. If these calibrations and checks are not done, the method can be very inaccurate indeed. For example, a winemaker once approached us as he thought our F SO2 results were too low – they were about half of what he was getting. Upon visiting his winery lab it was obvious that the airflow going through his apparatus was too high. The airflow was not checked or monitored in any way. We turned down the airflow considerably and even without calibrating the airflow his results were much closer to what we were getting for the same wine. The lesson for him was that he had assumed he was correct but had not checked some critical parameters of his testing setup.

Checks to be done on the AO method

To maintain ISO17025 accreditation for this method in our labs, we must do a number of extra steps and checks that are not normally done in many winery labs. Below are some of these extra steps, with details on how to go about the procedure. These don’t essential, but if you want to be sure you are getting the best results, they are highly recommended:

-

Airflow

According to the original work done on this technique for wine, the flowrate through the apparatus must be 1 L/min. Various flowmeters can be used to check the flowrate, however we use a soap bubble flowmeter of known volume and a timer that is regularly calibrated. The setup also requires a manometer to keep a visual guide to ensure the flow rate is correct. Simple vacuum pumps, such as aquarium pumps, can be rigged up with a variable valve so that the flowrate can be adjusted. This is very easy to set up and we have found it to be a critical parameter to get right.

-

Volumetric glassware

In our labs we are required to use certified volumetric glassware. That is, each item must have a certificate from an accredited authority that it measures volumes accurately; for example, the pipette used for measuring the volume of wine sample. This may seem overkill, but it is an important aspect of the test and so a reasonable thing for an accredited lab to do. You will simply not get an accurate result with this test if the critical volumes aren’t measured accurately. Not all reagents need to be measured very accurately, only those that have an impact on the final result: the sample volume and the volume of the titrant. We use only Class A volumetric pipettes and burettes for these steps.

-

Standardising the sodium hydroxide solution

Any solutions used in the quantitative measurement, in this case the sodium hydroxide, must be standardised on a regular basis to ensure the concentration used in the calculations is indeed correct. If you want to get accurate results to 2 significant figures (for example 25 ppm) then the sodium hydroxide concentration also needs to be accurate to at least 2 significant figures.

Standardising the sodium hydroxide may seem onerous, but again, if you don’t know the concentration accurately, your final SO2 result will not be accurate. The standardisation is quite straightforward and is best done with a primary standard material such as potassium hydrogen phthalate, although a simpler, but less accurate way, is to use a secondary standard such as 0.100 M HCl. Either way it should be done regularly; we do this monthly.

-

Sample handling

This not part of the test procedure and it seems most wineries already do this, but it is worth mentioning: all samples received in the lab should be tested as soon as the sample container is opened. This is because the SO2 can be depleted very rapidly once the container is opened, again having an impact upon the accuracy of the test. Its also best to use fresh samples for the same reason.

How to check that your results are accurate

Again, these are steps that as an accredited lab we are required to do to keep our accreditation for this test. They are not onerous and do have to be done at regular intervals, but if you agree that this is a critical test parameter, then they are highly recommended:

-

Proficiency programs

As stated in previous articles, we are fortunate in Australia to have the well-run and cost effective Interwinery Analysis Group (IWAG) as a source of wines for checking your testing performance. To perform well in a proficiency program is a requirement for keeping our ISO accreditation. If you are not an IWAG member you should be! For details see www.interwinery.com.au

-

Using standard solutions of sulfur dioxide

To be sure the results obtained are accurate, a standard solution or check standard should also be run regularly – we use a cask wine and monitor the results on a control chart. Using a cask wine daily as a sample is an easy way to check how your SO2 testing is going.

Conclusion

ISO17025 accreditation is a lot of work and is also very expensive and we are not suggesting wineries need to go this far. However, if you are not doing all the actions listed above that are required by an ISO17025 lab like ours, then you cannot be sure of the accuracy of your in-house testing for SO2. Some of these practices are easy to implement and we have managed to convince some of our clients to make these modifications to their testing. And of course, we have convinced others that using test kits with a spectrophotometer or discrete analyser removes the need for Aspriation/Oxidation completely, and is a much easier and accurate way to go!

Vintessential Laboratories are dedicated to helping our customers discover production problems early, understand them, and then fix them. At our laboratories around Australia we test hundreds of samples every week, so there’s hardly a problem we haven’t seen. Our articles bring you some of the recent problems that have been sent to us and explain how, working with our clients, we managed to solve them. Greg Howell founded Vintessential Laboratories in 1995; he can be contacted by email on [email protected]/. More articles on related topics are available on the Vintessential website: www.vintessential.com.au/resources/articles/