Interwinery Analysis Group finds best test for sugars in wine

Carly Gamble and Greg Howell

Introduction

Determining the sugar content of juice and wine is an essential part of the winemaking process. Glucose and fructose are the most abundant sugars naturally present in grapes and they are also fermentable sugars – their presence in finished wine leaving the wine susceptible to spoilage. Accurate monitoring of glucose and fructose levels are therefore essential throughout fermentation, however they can be tested in different ways and the different tests have advantages and disadvantages. A recent Interwinery Analysis Group (IWAG) survey has found the enzymatic test is the most popular way to test for these important wine components.

Methods for determining the sugar content of wine

The sugar content in wine has historically been analysed by determining the level of so-called reducing sugars by using methods such as the Lane & Eynon and the Rebelein method. These methods required simple apparatus and so were employed before modern lab instruments became available. They are both based on the fact that reducing sugars can react with cupric (Cu+) tartrate under alkaline conditions, with the resultant excess cuprous (Cu2+) ions determined indirectly by titration.

However, while glucose and fructose are indeed determined using these methods, other reducing sugars such as pentoses are also included in the results. Pentoses in wine are generally not fermentable and are therefore of little significance to the winemaking process. Using these results to judge the completeness of fermentation can be inaccurate – that is, reducing sugars are not equivalent to fermentable sugars. Despite the disadvantages, these reducing sugar methods continue to be used due to the simple apparatus needed and the low operating cost.

More recent methods used for determining the sugar content in wine are specifically designed to measure the fermentable sugars glucose and fructose. These include the enzymatic technique using a visible spectrophotometer and also the indirect technique of Mid Infra-Red (MIR) spectrophotometers (1).

Interwinery Analysis Group findings on wine sugar testing

A recent survey conducted by the IWAG established that there are three methods most commonly used for determining the sugar content of wine (2). By far the most frequently used of these methods amongst the survey respondents was the use of enzymatic analysis. The other two techniques were the reducing sugar tests – the Rebelein titration and the Lane and Eynon titration.

The IWAG survey analysed the submissions of 79 member laboratories and compared their glucose and fructose results. The ease of use and accuracy of enzymatic test kits has led to the majority of laboratories (77%) adopting this approach for routine analysis of glucose and fructose levels. Statistical analysis revealed that enzymatic measurement of glucose and fructose was more precise (generally narrower standard deviation range) compared to either of the two reducing sugar tests (2).

Enzymatic tests are based on the measurement of glucose and fructose only, which means that quantification is independent of the wine matrix. This technique also negates having to decolourise most wine samples before analysis (except very highly coloured samples), an important time-saving advantage of using enzymatic test kits. Furthermore, the IWAG survey revealed a larger deviation from the mean for the results obtained by the reducing sugars tests in both white and red wines. This indicates that other components in the wine can also interfere with these methods, which is not the case when using enzymatic test kits.

Mid Infra-Red techniques

A statistical analysis of a set of IWAG proficiency results revealed a significant difference between the mean glucose and fructose values obtained for a red wine using MIR technologies as compared to those obtained using enzymatic testing (1). The lack of accuracy obtained at levels below 1g/L are also cause for concern with MIR technologies.

The majority of calibration data sets supplied with MIR instruments are developed in Europe and therefore should be replaced with calibrations developed with wine that is from the specific region(s) where the instrument is used (1). The enormous amount of time it takes to set up new calibration data sets means that many wine laboratories do not perform this essential development work. Failure to do so inevitably leads to errors, some very large.

The ease of calibration when using enzymatic tests kits is therefore another significant advantage to this approach when compared to MIR technologies. Enzymatic testing is also more accurate at low levels, and for those wines containing high glucose and fructose levels a simple dilution of samples is the only sample preparation required.

Instrumentation for enzymatic glucose and fructose analysis

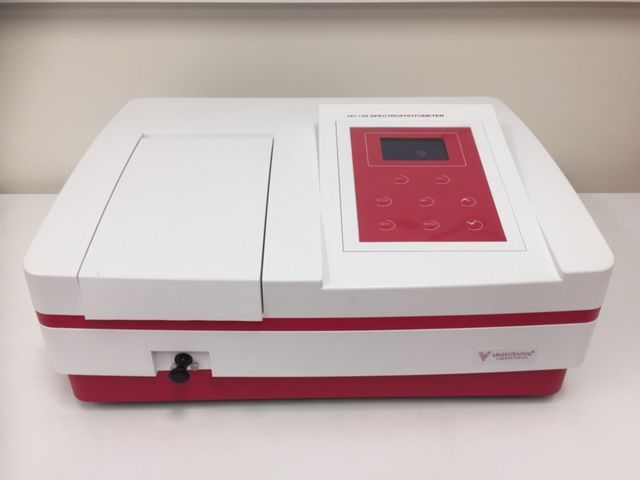

A visible range spectrophotometer is all that is required and these can be purchased for a minimal initial outlay – there are now models on the market for less than A$2000 (for example see Figure 1). The benchtop spectrophotometer method requires enzymatic reagents and these are usually bought in test kit format.

Fig. 1 Vintessential UV Visible Spectrophotometer UV-120

Although a reasonable throughput of samples can be achieved using the benchtop spectrophotometer method (10-20 per hour), larger automated spectrophotometric analysers have been available for several years and are now relatively well priced. These instruments are more commonly known as discrete analysers as each sample is treated discretely (individually). This allows several tests to be done on each sample. Different tests can also be done on each sample, for example, sample 1 may have glucose and fructose tested, sample 2 these plus malic acid etc.

The other main advantage is that the number of samples tested on these instruments can be up to 200 per hour (for example the Chemwell 2910 – see Figure 2). So despite the larger capital initially required to purchase these automated instruments, the huge throughput, the low operator time needed, the ease of calibration and the use of the specific enzymatic test kits designed for discrete analysers provides enormous productivity improvements in the wine lab.

Fig. 2 Vintessential Chemwell 2910 Discrete Analyser

Getting the most out of your results

In order to ensure the best results, it is essential to routinely perform a number of quality control checks. In our NATA accredited labs these include running a glucose and fructose standard of known concentration and running a control cask wine sample each day. This ensures the repeatability and reproducibility of the test which are both important determinants for the precision of the analysis. A way to determine how closely the result represents the true value is by routinely performing spike analysis. This is done by adding a known amount of a standard solution to one of the test samples, then analysing the glucose and fructose in both the spiked and un-spiked sample. Easy to perform, these quality control checks will ensure that your results are accurate.

Conclusion

When the Interwinery Analysis Group reviewed the most common laboratory techniques for testing sugars in wine, they found that the enzymatic technique was the most popular and the most precise. After the enzymatic method, the reducing sugar titrations (Rebelein and Lane & Eynon) were the next most used whilst the Mid Infra-Red (MIR) was the least favoured. The advantages of using the enzymatic technique include: highest precision, lowest cost equipment, best results at low sugar concentrations and no interferences from other wine constituents such as non-fermentable sugars and colour components. The enzymatic technique can also be used with automated analysers that provide enormous productivity improvements in medium and large wine laboratories.

References

1. Wilkes, E; Warner, L; Accurate mid-infrared analysis in wine production – fact or fable? Wine and Viticulture Journal, May/June, 2014, 64-67.

2. Wilkes, E; Warner, L ; Sugar Analysis – too many choices? Wine and Viticulture Journal, May/June, 2016, 68-72.

Dr. Carly Gamble is the Western Australian State Manager for Vintessential. Greg Howell founded Vintessential Laboratories in 1995, he can be contacted by email on [email protected]/.

Copyright© 2016 Vintessential Laboratories. No part of this publication may be reproduced in any form or by any means without the permission in writing from the copyright owner