Malo-Lactic Fermentation Vacation, Patulin in Apple Products and Sucrose Testing in Sparkling Base Wine – Testing Times Jan 2018

MLF and holidays

Would you think there is a connection between vacations and malo-lactic fermentation (MLF)? Here is an example of such a connection.

Recently we received a problem sample of wine that had not completed MLF. The winemaker, who had been away for a winter holiday, had added a large dose of sulfur dioxide to the wine to stop the MLF, which was already underway. Upon return to the winery he tested the wine for malic acid by TLC and discovered that MLF was still incomplete. He then tried, unsuccessfully, to restart the MLF before coming to see us.

We advised that the key parameters of pH, free and total sulfur dioxide, alcohol and malic acid should be determined as it is important to know these accurately. Our tests showed that there was still considerable malic acid (over 1 g/L) and that the pH was relatively high. So far so good. However the sulfur dioxide content was at the upper limit of suitability for re-inoculation. Most importantly the alcohol content was around 16% – the MLF bacteria were up against some pretty difficult conditions, particularly the high alcohol content and relatively high sulfur dioxide levels.

A suitable MLF bacterial strain that could tolerate high alcohol content and relatively high sulfur dioxide was needed, and as the wine was going to be difficult to get through MLF, a careful, planned and time-consuming approach to MLF was required.

An easier way for the winemaker to take a winter holiday would be to use co-inoculation of yeast and MLF bacteria, instead of sequential inoculation of the MLF bacteria. A high potential alcohol is a warning sign that sequential MLF will struggle and that the use of a co-inoculant bacteria will make the fermentation of the malic acid much easier. The main advantages of co-inoculation include starting the MLF whilst the level of alcohol is low, the bacteria gaining access to nutrients in the must that have not yet been chewed up by the yeast in the primary fermentation, having low sulfur dioxide levels and finally, removing the need to heat the wine, as it will already be at a reasonably high temperature due to the yeast fermentation.

Sucrose testing in sparkling base wine

Two samples of wine with the same name were received from another customer and the request was to test each sample for glucose and fructose – the sugars that are present in grapes and that decrease in concentration during yeast fermentation. The results showed that both samples had minimal glucose and fructose.

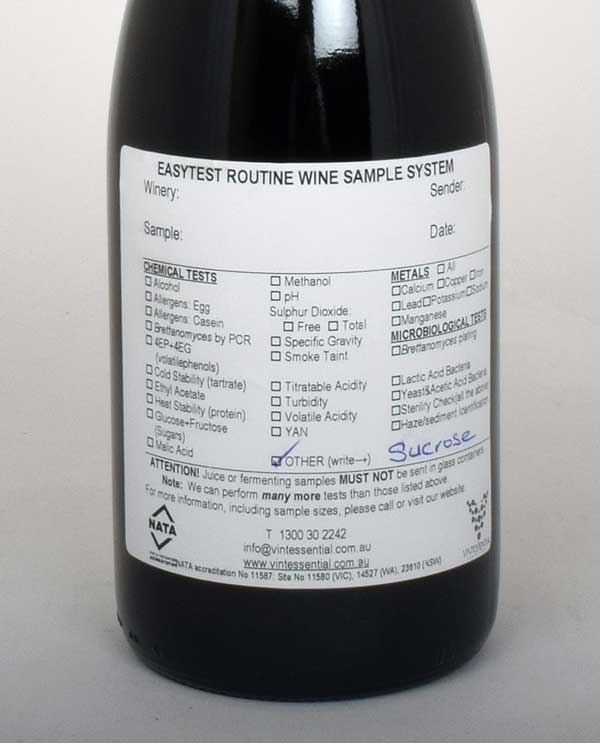

As a consulting laboratory, we simply test what we are requested to do. To assist our customers we provide free sample bottles and labels. Samples usually arrive with a box ticked as to what testing is required, so we do the testing and report the results.

However in this case our keen-eyed staff picked up a few clues that the two samples of wine were most likely a sparkling wine base before and after cane sugar (sucrose) had been added at the tirage stage. Sucrose is normally added at this point in the production of sparkling wine, producing a total sugar content typically of around 24 g/L to give the required amount of carbon dioxide after the second yeast fermentation in the bottle.

The winemaker was contacted and asked if this was the case. Yes, indeed it was and they agreed that they actually needed the wine tested for glucose, fructose and sucrose. Not surprisingly, the total sugar content was around the expected level in the mid-20s.

Although sucrose is a disaccharide composed of glucose and fructose, sucrose doesn’t cleave to these two monosaccharides under normal testing methods hence the need to know the content of all three sugars.

Without knowing the total sugar content of a sparkling wine base, it is impossible to determine the correct amount of sucrose to add during tirage, to ensure a successful secondary fermentation.

If we had simply reported glucose and fructose as originally requested, the winemaker may have been under the impression there was little sugar in the wine and added another dose of sucrose. This would have fermented in the bottle, producing more carbon dioxide than required with the related increase in pressure in the bottle – not a good outcome.

So the lesson here is to make sure when testing sparkling base that total sugars, including sucrose, are tested prior to the secondary fermentation.

The presence of the mycotoxin Patulin

The beauty of working with fermented beverages is that there always seems to be something new to learn. Recently we have learned a lot about patulin – a mycotoxin (a toxic fungal metabolite) that is produced by certain moulds such as Penicillium and Aspergillus. These moulds can grow on many fruits and are commonly found on apples. The presence of patulin in foods is undesirable and regulated in many countries, due to its toxic nature. And worryingly, patulin is heat stable and therefore not destroyed by pasteurisation, so early detection is imperative.

As we are now testing more apple cider and apple juice, we are also regularly testing for patulin by HPLC. This is a great analytical technique for separating out multiple compounds and detecting them at very low levels. Some producers test for the presence of patulin prior to processing every batch of apple juice.

The level of patulin in apple products, including juice and cider, is widely regulated around the world. As recently as this year, two Australian apple juice products had to be removed from supermarket shelves in Hong Kong due to elevated patulin levels. The levels we are talking about are very low, with most overseas markets specifying upper limits of 50 ug/kg (50 ppb). This level does vary depending upon the apple product produced, and in some markets the level is much lower for products destined for babies and infants. For example it is 10 ppb in apple juice for infants in the EU.

As previously mentioned, the production of craft cider is strong and still growing. This is one analysis that cider makers should be aware of. And remember, it comes from mouldy fruit – clean fruit won’t have patulin. So don’t panic, but be aware it is a regulatory requirement in many countries.

Vintessential Laboratories are dedicated to helping our customers discover production problems early, understand them, and then fix them. At our five laboratories around Australia we test hundreds of samples every week, so there’s hardly a problem we haven’t seen. Every month we bring you some of the recent problems that have been sent to us and explain how, working with our clients, we managed to help solve them. Greg Howell founded Vintessential Laboratories in 1995; he can be contacted by email on [email protected]/.